The Canadian Institute of Mining, Metallurgy, and Petroleum (“CIM”) hosts a yearly convention designed to curate and showcase the very best of examples of mining and manufacturing leadership in both Canada and world-wide. Over 5,000 participants are expected from over 40 countries, with nearly 500* companies exhibiting at the CIM EXPO as a part of the Convention. The theme of this year’s convention is thinking differently about challenges in the industry, and searching for best practices to overcome them. In line with this theme, WEGU Manufacturing will be showcasing a wide variety of its best rubber and plastic product solutions at the show.

The Convention schedule includes 3 full days of technical presentations, spanning 12 unique themes. Topics range from physical and environmental safety to subterranean mining. Outside of technical presentations, the Convention presents fantastic opportunities to network with industry leaders and learn from the best in the mining/manufacturing industries. WEGU will be present for the entirety of the Convention, to learn from agile newcomers and also contribute the benefits of it’s many decades of experience in manufacturing resolution to difficult problems.

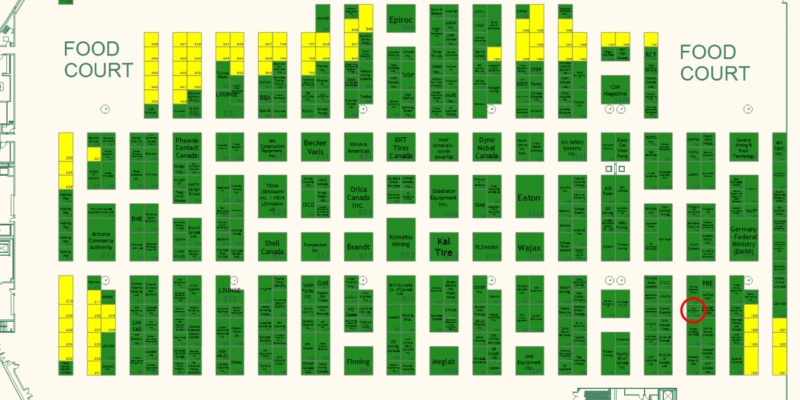

The EXPO gives opportunity for companies to produce examples of the best product solutions available, world-wide. WEGU will be showcasing its wear-resistant impact materials, impact bars, draft gear box bumpers, idler impact tires, slurry pump casing liners, isolation pads, bumper boards, shaker screen balls, and more. WEGU’s booth, 1609 (row 16, booth 9) is located near the main entrance. WEGU Manufacturing welcomes all to visit and inquire for tailored solutions to their rubber or plastic needs.

*as of this article’s publishing