WEGU Dunlop Adjustable Gasket Blog

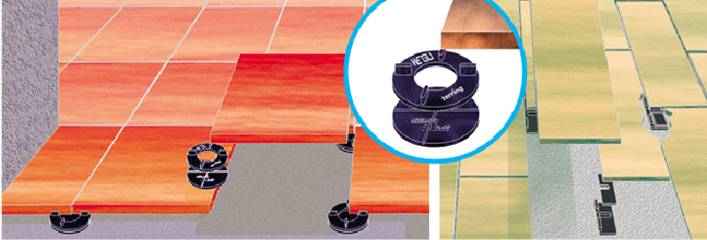

ADJUSTABLE: Can be stretched to desired size and can be repositioned to seal some covers, which are pitted and not smooth.

COMPRESSION: Compresses easily without heavy torquing pressure. This avoids breaking yolk on cover.

FAST INSTALLATION DUNLOP GASKET is easy to remove and clean from cover surface and even easier to replace.

DIFFERENT COLOUR MODELS: Unlike other Manufacturers that make only 1 colour, black for both water and steam purposes.

WEGU MANUFACTURING produces the DUNLOP ADJUSTABLE GASKETS in RED and BLACK.

RED DUNLOP FOR WATER: Handhole and Manhole Gaskets

BLACK DUNLOP FOR STEAM: Handhole and Manhole Gaskets

DISTRIBUTION

Throughout Canada by SHAFTER HYDRONICS AND STEAM

259 Van Horne Ave. Montreal Quebec H2V 1H9

Tel: 514-274-8347 Fax: 514-274-7652 Toll Free 1-800-361-1778

Email: info@steamexperts.com

URL: www.steamexperts.com